Why Is Laminated Glass Called Safety Glass?

Why Is Laminated Glass Called Safety Glass?

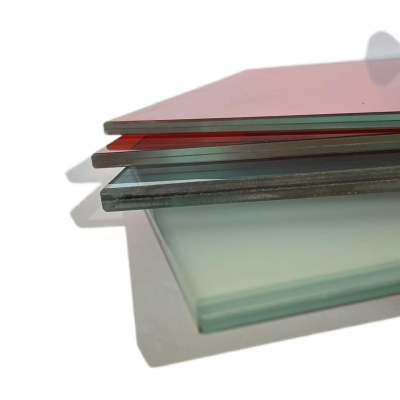

Laminated glass is a type of safety glass made by sandwiching a layer of PVB (Polyvinyl Butyral) or SGP (Sodium-Glass Polyvinyl) film between two or more layers of glass, and then bonding them together under high heat and pressure. It has features such as impact resistance, explosion resistance, sound insulation, and UV protection, and is widely used in applications like building windows, curtain walls, skylights, and railings.

1. Structure and Principle of Laminated Glass

1.1 Basic Structure

Outer Layer: Material: Tempered Glass (typically)

Function: Provides strength

Middle Layer:Material: PVB/SGP Film (0.38mm\~2.28mm)

Function: Bonds the glass, absorbs impact energy

Inner Layer: Material: Tempered/Regular Glass

Function: Enhances safety

Common Thickness Combinations:

5+0.76 PVB+5 (5mm glass + 0.76mm film + 5mm glass)

6+1.14 PVB+6 (Higher impact resistance)

8+1.52 SGP+8 (Used for high-rise buildings and explosion-proof applications)

1.2 Core Principles

Viscoelastic Cushioning: The PVB film absorbs impact energy. Even if the glass breaks, the fragments remain stuck to the film, preventing dangerous shards from scattering.

Sound Damping: The middle layer effectively blocks mid-to-low frequency noises (such as traffic sounds).

UV Filtering: The PVB film blocks over 99% of UV rays, which helps protect indoor furniture from fading.

For example: Car windshields will not shatter into sharp pieces when struck by stones.

2. Five Major Advantages of Laminated Glass

(1)Safety and Explosion-Proof:

After breaking, laminated glass does not produce sharp shards, providing protection against falls, theft, or impact.

(2)Sound Insulation and Noise Reduction:

More effective than hollow glass for mid-to-low frequency noises (like traffic and airplanes).

(3)UV Protection:

Blocks 99% of UV rays, protecting indoor furniture and floors from fading.

(4)Impact Resistance:

Can resist flying debris from storms, hail, or even bullets (with the right thickness).

(5)Structural Stability:

Ideal for large glass panels, such as frameless glass doors or cantilevered canopies.

---

3. Laminated Glass vs. Insulated Glass Comparison

Safety: Laminated glass: Very high (explosion-proof and shatterproof); Insulating glass: Average (may break off after shattering);

Sound insulation: Laminated glass: Better for low- and medium-frequency noise; Insulating glass: Better for high-frequency noise (such as human voice);

Heat insulation: Laminated glass: Average (requires Low-E coating); Insulating glass: Excellent (insulated hollow glass);

Applications: Laminated glass: Sun roofs, guardrails, curtain walls; Insulating glass: Doors, windows, and exterior windows;

Price (㎡): Laminated glass: 200-800 yuan (depending on thickness); Insulating glass: 100-400 yuan.

Best Combination: Laminated Insulated Glass (e.g., 5+0.76 PVB+5+12A+5) balances safety, soundproofing, and thermal insulation.

---

4. Three Types of Laminated Glass Interlayer Materials

(1) PVB Laminated Glass (Most Common Choice)

Advantages: Low cost, mature technology, meets soundproofing and explosion-resistant standards.

Disadvantages: May yellow under high temperatures (UV-resistant versions are available for long-term exposure).

(2)SGP Laminated Glass (High-End Upgrade)

Advantages: 5 times stronger than PVB, higher transparency, suitable for ultra-white glass.

Disadvantages: 2-3 times more expensive than PVB (e.g., 8+1.52 SGP+8 costs about 600 RMB/m²).

(3)EVA Laminated Glass (Rarely Used)

Advantages: Can be used for colored interlayers (for decorative purposes).

Disadvantages: Prone to aging, less safe than PVB/SGP.

---

5. Four Major Applications of Laminated Glass

(1)Skylights

Reason to Choose: Prevents glass from shattering and falling, and can withstand hailstorms.

Recommended Configuration: 6+1.14 PVB+6 (Northern regions may need additional tempered insulated layers).

(2)Street-facing Windows

Reason to Choose: Superior soundproofing compared to insulated glass.

Recommended Configuration: 5+0.76 PVB+5+12A+5 (Laminated Insulated Glass Combination).

(3)Glass Railings/Stairs

Reason to Choose: Will not shatter into dangerous fragments upon impact.

Recommended Configuration: 8+1.52 SGP+8 (For ultra-high strength).

(4)Bank/Jewelry Store Windows

Reason to Choose: Provides theft and impact resistance, delays break-in time.

Recommended Configuration: Multi-layer laminated glass (e.g., 10+1.52 PVB+10+1.52 PVB+10).

---

6. Frequently Asked Questions

(1)Does laminated glass have a self-explosion risk?

The self-explosion rate of tempered laminated glass is about 3‰, but the fragments are held in place by the film, so there is no risk of them falling.

(2)How to identify genuine laminated glass?

Edge Check: Genuine laminated glass has a film layer (without air bubbles or delamination).

Tap Test: The sound should be dull (while hollow glass has a clearer, crisper sound).

7. Purchasing Recommendations

For Home Windows: Choose PVB Laminated Insulated Glass (e.g., 5+0.76 PVB+5+12A+5).

For Skylights: Choose 6+1.14 PVB+6 or add insulated layers.

For High-Security Needs: Choose SGP Laminated Glass (e.g., 8+1.52 SGP+8).

Verification: Always request the manufacturer's PVB/SGP warranty certificate.

Conclusion: The core value of laminated glass is safety and sound insulation . For regular windows, insulated glass is sufficient, but for special scenarios, upgrading to laminated glass is recommended!

---

Let me know if you'd like any adjustments or further clarifications!