- Tempered Glass

- Laminated Glass

- Tempereed Laminated Glass

- Insulating Glass

- Silk Screen Printing Glass

- Ceramic Digital Printing Glass

- Curved Glass

- Padel Glass

- Solar Panel Glass

- Shower Glass

- HOME

- Laminated Glass

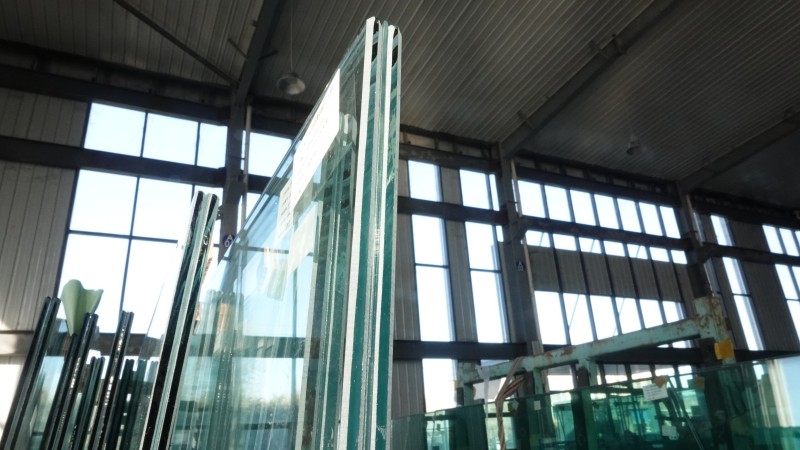

- Customized Tempered Laminated Glass

Customized Tempered Laminated Glass

📞 Contact Us

📧 Email : intl@wenshengglass.com

📱 WhatsApp /phone : +86 188 6688 9570

Advantages of Laminated Glass

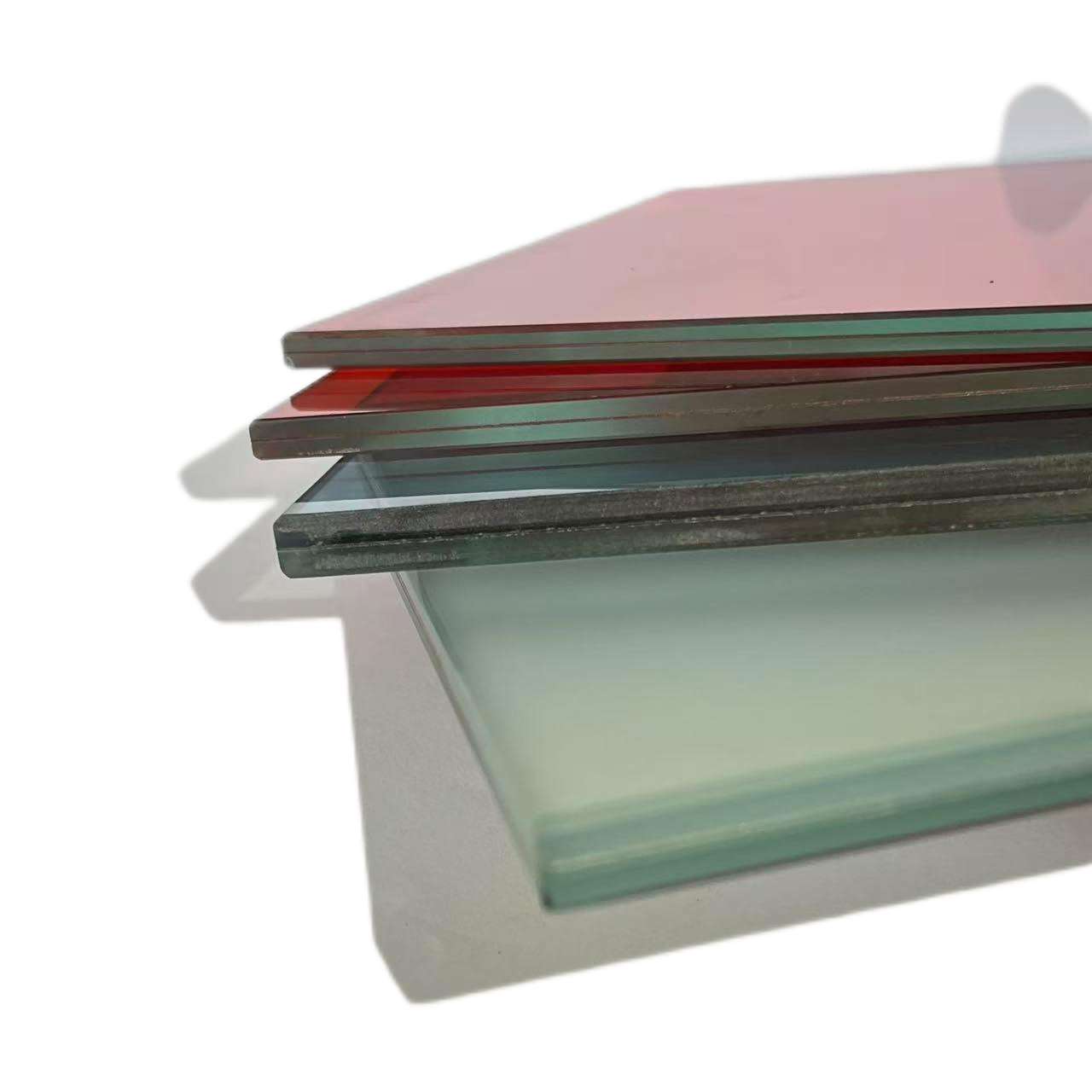

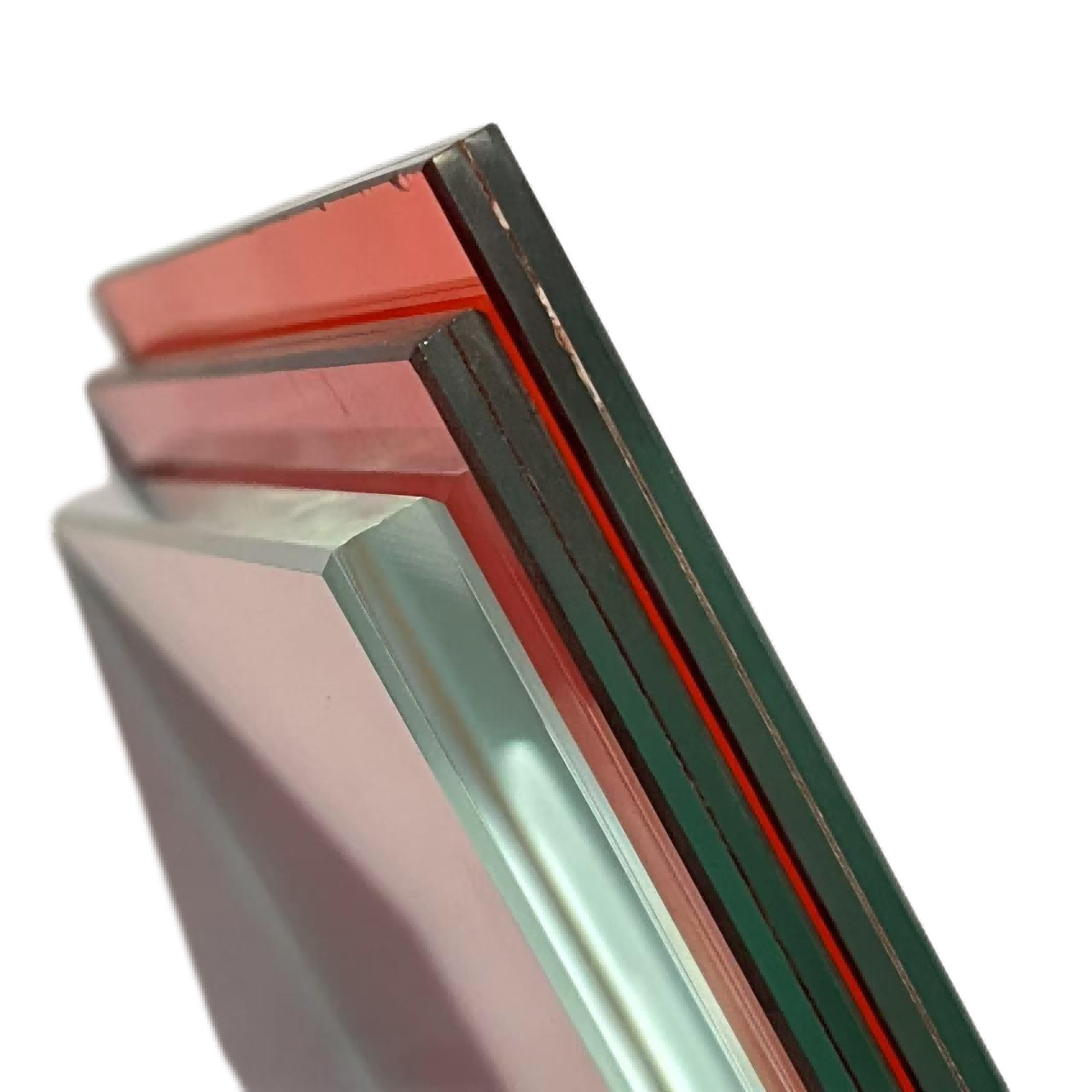

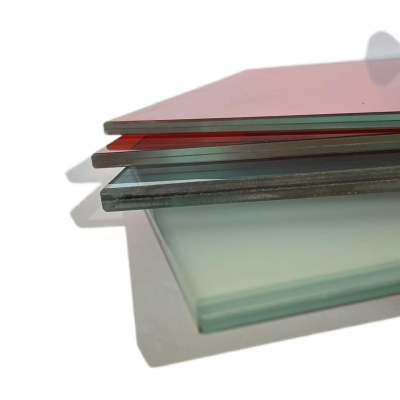

1. Diverse Types of Laminated Glass

We offer various types of laminated glass to suit different safety, design, and performance needs:

Clear Laminated Glass – Standard safety glass for general architectural use.

Tempered Laminated Glass – Combines the strength of tempered glass with the safety of lamination, ideal for high-impact areas.

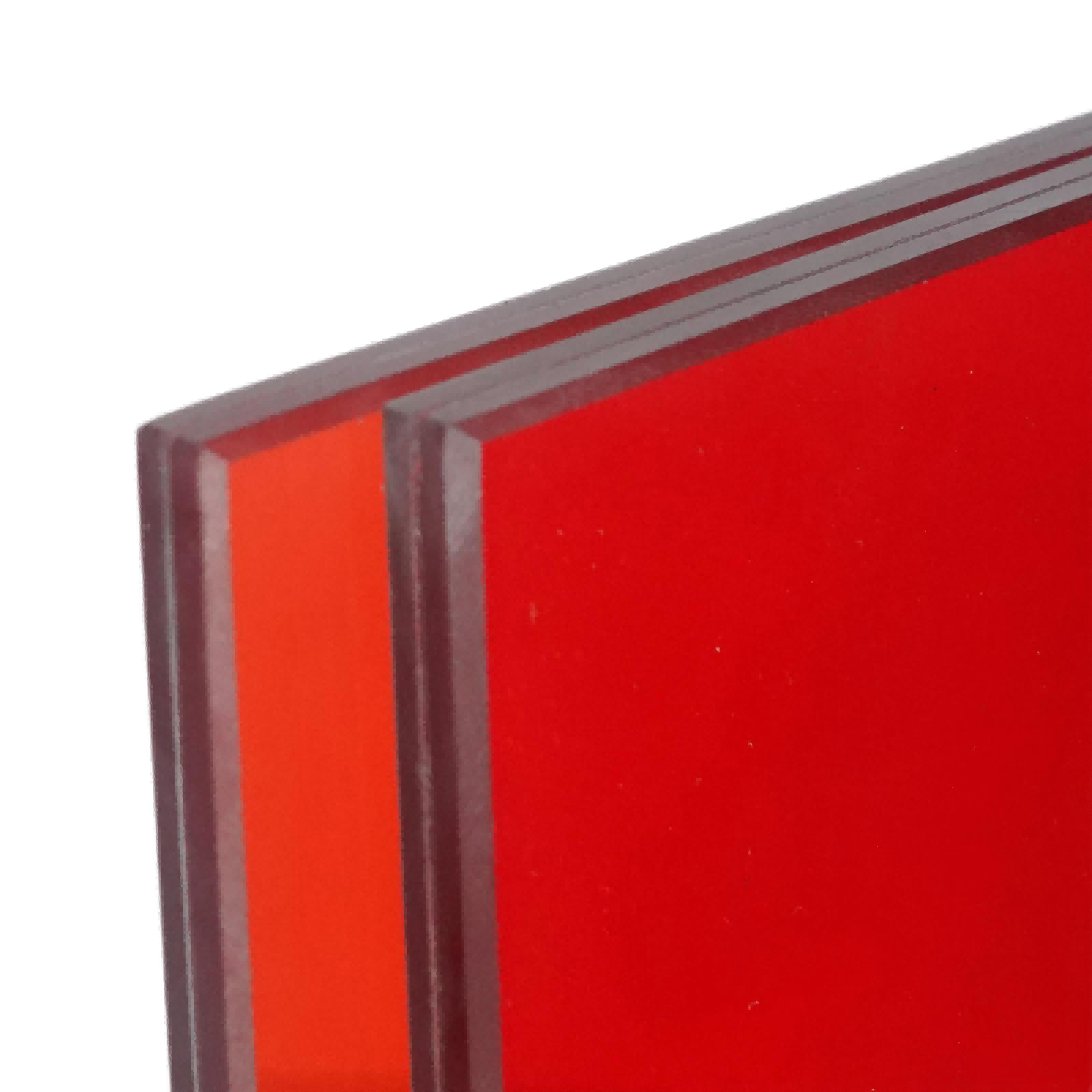

Colored Laminated Glass – Adds aesthetic appeal and privacy through tinted interlayers.

Printed Laminated Glass – Custom graphics or patterns embedded between layers for decorative applications.

Acoustic Laminated Glass – Special soundproof interlayers to reduce noise transmission.

Bullet-Resistant Laminated Glass – Multi-layer configuration designed to resist ballistic impact, used in high-security environments.

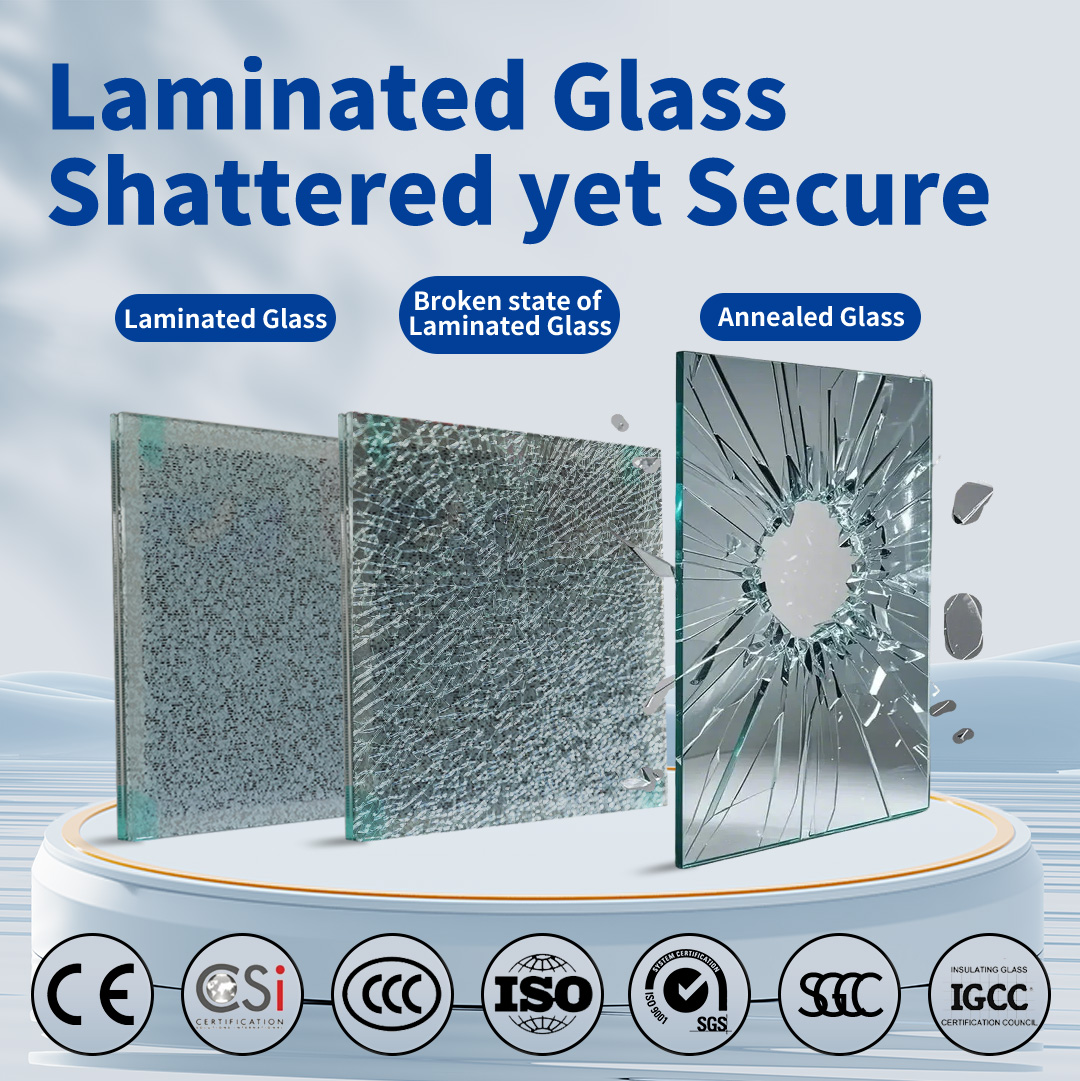

2. Superior Safety

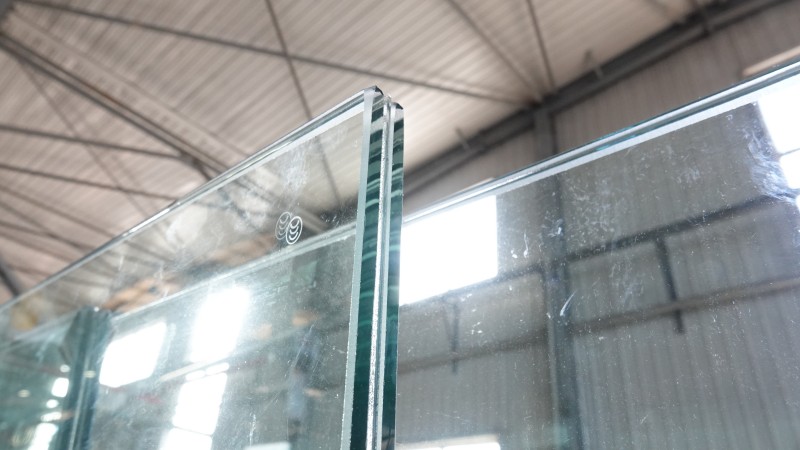

Laminated glass consists of two or more layers of glass bonded with PVB or SGP interlayers. When broken, the glass fragments adhere to the interlayer, preventing shattering and reducing the risk of injury.

3. High Impact Resistance

Compared to ordinary glass, laminated glass offers significantly stronger resistance to blows, pressure, and external forces. It’s suitable for skylights, balconies, and glass façades that require robust structural integrity.

4. UV Protection

The interlayer effectively blocks over 99% of ultraviolet radiation, protecting interior furnishings, artwork, and occupants from UV-related damage.

5. Excellent Sound Insulation

Laminated glass reduces noise transmission thanks to the damping properties of the interlayer. It is ideal for use near airports, highways, or in commercial and residential buildings requiring acoustic comfort.

6. Explosion & Intrusion Resistance

Even when damaged, laminated glass remains intact, offering a barrier against break-ins, vandalism, and explosions. It is widely used for storefronts, security doors, and sensitive facilities.

7. Customizable Aesthetics

Laminated glass allows for a wide range of customizations—colors, prints, patterns, and even integration with smart technologies (e.g., switchable privacy glass)—to meet both functional and architectural design needs.

| Category | Parameter | Standard Example | Technical Notes |

| Dimensions | Min. Size | 300×300 mm | Most sizes customizable |

| Max. Size | 3300×13000 mm | ||

| Structural Composition | Glass Layer Thickness (mm) | Single layer: 3+3, 5+5, 6+6 | Thickness affects load-bearing and impact resistance. |

| Double layer: 6+6+6, 8+8+8 | |||

| Interlayer Material Type | PVB (Standard, 0.38/0.76/1.52mm) | PVB: Cost-effective; SGP: 5x stronger than PVB; EVA: Ideal for curved glass | |

| SGP (High-strength, 1.52/2.28mm) | |||

| EVA (Flexible) | |||

| Visible Light Transmittance | Transparent PVB: 88%~92% | Customizable colors/patterns. | |

| Colored PVB: 40%~70% | |||

| Frosted PVB: 50%~60% | |||

| Safety Performance | Impact Resistance Rating | EN 12600 1B1 (5mm+0.76mm PVB+5mm) | Passes 1040g steel ball drop test from 4.8m height with safe breakage pattern |

| 2B2 (8mm+1.52mm PVB+8mm) | |||

| Post-Breakage Behavior | PVB: Fragments adhere to interlayer | Complies with BS 6206 safety standards | |

| SGP: Cracks without shattering | |||

| Optical Distortion (Waviness) | ≤0.1% (ASTM C1048 compliant) | High-precision lamination reduces deformation. | |

| Mechanical Performance | Bending Strength (MPa) | 6mm laminated: ≥50 | Static load test (ASTM C1172). |

| 8mm laminated: ≥70 | |||

| Edge Peel Strength (N/mm) | PVB: ≥15 | Maintains ≥90% strength after humidity aging tests | |

| SGP: ≥25 | |||

| Processing | Pre-press Temperature/Pressure | PVB:120~200℃/1.2~1.5MPa | Ensures bubble-free bonding. |

| SGP:135~200℃/1.5~2.0MPa | |||

| Autoclave holding/pressure maintenance time | PVB: 45~60 minutes | Pressure: 1.25 MPA | |

| SGP: 1~1.5 hours | |||

| Edge Treatment | Edgie polishing process | Rough grinding | Reduces stress concentration during installation. |

| Fine grinding | |||

| Special design | Curved glass bending radius | ≥500mm | Cold bending requires flexible compatibility of interlayer materials |

| Production Capacity | Daily Output: 14,000 m²/day Expedited Capacity: 20,000 m²/day | ||

Related Products

Related News

Submitted successfully

We will contact you as soon as possible