- Tempered Glass

- Laminated Glass

- Tempereed Laminated Glass

- Insulating Glass

- Silk Screen Printing Glass

- Ceramic Digital Printing Glass

- Curved Glass

- Padel Glass

- Solar Panel Glass

- Shower Glass

- HOME

- Insulating Glass

- Customized Insulated Glass

Customized Insulated Glass

📞 Contact Us

📧 Email : intl@wenshengglass.com

📱 WhatsApp / Phone: +86 188 6688 9570

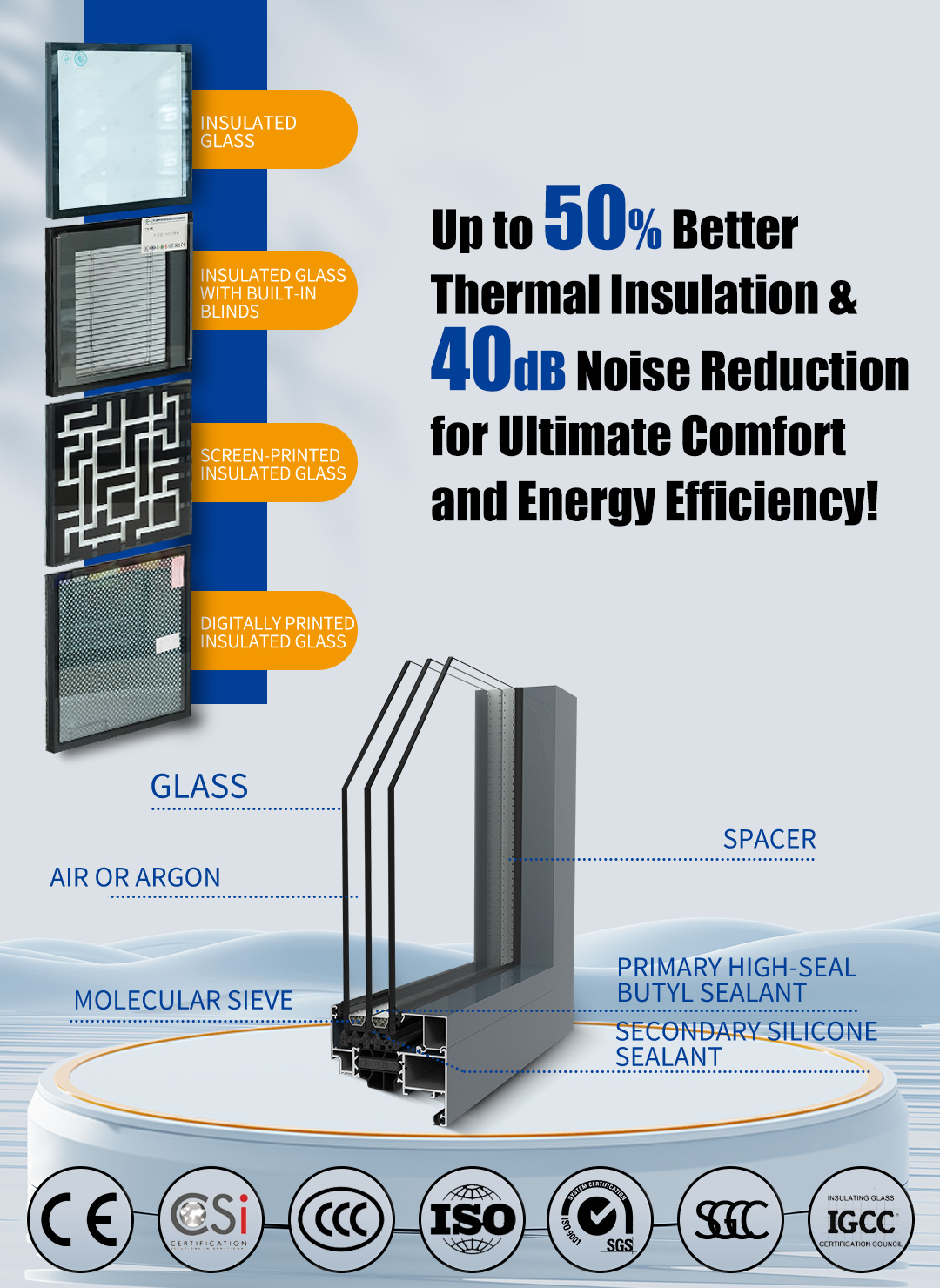

Advantages of Insulating Glass

1. Types of Insulating Glass

We offer a variety of insulating glass options to meet diverse architectural, thermal, and aesthetic requirements:

Double-Pane Insulating Glass – The most common structure, ideal for residential and commercial use, offering excellent thermal and sound insulation.

Tempered Insulating Glass – Adds safety and durability by combining tempered panes, often used in high-rise buildings.

Laminated Insulating Glass – Combines safety interlayers with insulation, suitable for areas requiring both security and energy efficiency.

Printed Insulating Glass – Integrates decorative or functional patterns for branding or design customization.

Low-E Insulating Glass – Features a low-emissivity coating to reduce infrared and ultraviolet light transmission, maximizing energy savings.

Triple-Glazed Insulating Glass – Offers superior insulation and noise reduction performance, used in extreme climates or premium constructions.

2. Energy Efficiency

The sealed air or inert gas layer between glass panes significantly reduces heat transfer, maintaining indoor temperature and lowering HVAC energy consumption year-round.

3. Sound Insulation

Insulating glass effectively minimizes noise transmission from outside, creating a quieter indoor environment—especially beneficial in urban, airport, or roadside locations.

4. UV Protection

Low-E and laminated options can block a large percentage of harmful ultraviolet rays, protecting interior furnishings, artworks, and human skin from UV-related damage.

5. Safety and Security

When combined with laminated or tempered glass, insulating units provide both thermal performance and high-impact resistance, ensuring structural safety and personal protection.

6. Condensation Resistance

By maintaining a stable internal temperature and reducing humidity transfer, insulating glass minimizes the risk of condensation forming on interior surfaces.

7. Aesthetic Flexibility

Available with multiple color tints, decorative grids, spacers, and coatings, insulating glass enhances building design without compromising function.

| Parameter class | Parameter Name | Standard Values | Description |

| Thermal Performance | U-value (W/m²·K) | Standard Double Glazing: 2.8~3.2 Low-E Double Glazing: 1.6~2.0 Argon Filling: ↓0.1~0.3 | Lower values indicate better thermal insulation |

| SHGC (Solar Heat Gain Coefficient) | Clear Glass: 0.7~0.8 Low-E Glass: 0.25~0.40 | Lower values reduce solar heat gain | |

| VLT (Visible Light Transmittance) | Clear Glass: 85%~90% Low-E Glass: 70%~80% Frosted Glass: 50%~60% | Affects indoor lighting brightness | |

| VLR (Visible Light Reflectance) | Clear Glass: 8%~12% Low-E Glass: 15%~25% | Higher reflectance reduces glare | |

| Acoustic Performance | Rw (Weighted Sound Reduction Index, dB) | 6mm Single Glass: 31 6+12+6 Double Glazing: 34 10+12+6 Double Glazing: 36 6+12+6.5 Laminated Glass: 38 | The higher the value, the stronger the sound insulation effect |

| Structural Parameters | Glass Thickness Combinations (mm) | 4+4, 5+5, 6+6, 10+6, 6+6.5 (laminated) | Optimize sound insulation/load-bearing |

| Spacer Material | Aluminum (high thermal conductivity) TPS Thermoplastic (warm edge) Stainless Steel (corrosion-resistant) | Warm edge spacers ↓U-value by 0.1~0.2 | |

| Spacer Width (mm) | 6, 8, 10, 12, 14, 16, 18, 20 (2mm increments) | Wider spacers ↑ insulation but ↑ weight | |

| Gas Filling | Air (standard) Argon (recommended, ↑U-value by 10%~15%) Krypton (premium, ↑U-value by 15%~20%) | Inert gases reduce thermal convection | |

| Glass Types | Basic Types | Clear Float, Low-Iron, Tinted (Gray/Blue/Green), Frosted, Patterned | Light transmittance of low iron glass ↑5%~10% |

| Functional Glass | Hard-coated Low-E (U-value 1.8~2.2) | Soft coating requires inner layer protection | |

| Soft-coated Low-E (U-value 1.6~1.8, requires inner protection) | |||

| Laminated Glass (anti-breakage/sound insulation) | |||

| Dimensions | Min. Size | 300×300 mm | Most sizes customizable |

| Max. Size | 3300×13000 mm | ||

| Sealing Process | Primary | Butyl Sealant | Gas leakage prevention (bonds spacers) |

| Secondary | Polysulfide (aging-resistant) | Silicone is suitable for high temperature areas | |

| Silicone (high-temperature areas) | |||

| Polyurethane (high strength) | |||

| Edge Design | Warm Edge Spacers | U-value Reduction vs. Aluminum↓0.1~0.2 | Recommended For High humidity areas |

| Condensation Risk30%~50% | |||

| Production Capacity | Daily Output: 14,000 m²/day Expedited Capacity: 20,000 m²/day | ||

Related Products

Related News

Submitted successfully

We will contact you as soon as possible