Differences Between Tempered Glass and Ordinary Glass

Differences Between Tempered Glass and Ordinary Glass

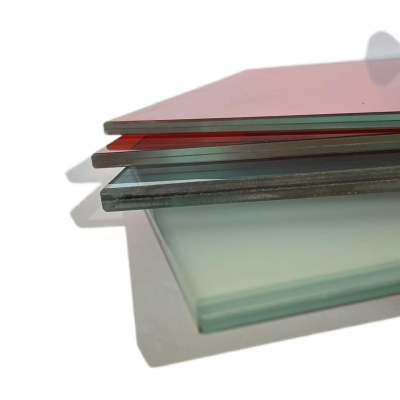

Tempered glass and ordinary glass are two widely used materials in modern architecture, home furnishings, and industrial fields. There are significant differences in its performance, manufacturing process and application scenarios. A thorough understanding of the differences between the two can help make more scientific choices in practical use. The following is a detailed analysis from multiple dimensions such as material properties, production processes, physical properties, safety performance, and application fields.

1. Differences in material properties and manufacturing processes

1.1 Ordinary Glass (Soda-lime Glass)

The main components of ordinary glass are silica (about 72%), sodium oxide (about 15%), and calcium oxide (about 9%), which are fused at high temperatures and then cooled to form the material. The manufacturing process includes steps such as raw material mixing, melting, molding (such as float process), and annealing. During the annealing process, the glass cools slowly to relieve internal stresses, resulting in a smooth surface but relatively high brittleness. The Mohs hardness of ordinary glass is approximately 6, allowing for cutting, drilling, and other secondary processes. However, its impact resistance is low, and it produces sharp fragments when broken.

1.2 Tempered Glass

Tempered glass is a product obtained by physical or chemical strengthening treatment on the basis of ordinary glass. The physical tempering process (the most common method) involves heating the glass to over 650°C, close to its softening point, and then rapidly cooling it with high-pressure air (quenching). This process creates a compressive stress layer on the surface (about 100-200 MPa) and internal tensile stresses, enhancing the strength of the glass by 4 to 5 times. Chemical tempering involves ion exchange to form a dense layer on the surface for strengthening. After tempering, the glass cannot be processed mechanically, and any cutting or hole drilling must be done before tempering.

2. Physical Property Comparison

2.1 Mechanical Strength

Tempered glass has a bending strength 3 to 5 times that of ordinary glass (about 120-200 MPa) and significantly better impact resistance. For instance, a 227g steel ball falling freely from a height of 2 meters and hitting tempered glass can remain intact, while ordinary glass may break at a height of 0.5 meters. In addition, tempered glass has better temperature difference resistance and can withstand a temperature difference of approximately 200°C (while ordinary glass is only 70-90°C), making it more suitable for high-temperature environments such as oven doors and curtain walls.

2.2 Fracture Pattern

When ordinary glass breaks, it produces sharp, long, strip-shaped fragments, which can easily cause cuts. In contrast, tempered glass breaks into small, blunt-edged particles in a honeycomb pattern (with particle size generally ≤50 mm²) due to the disruption of stress balance. This characteristic complies with safety glass standards (e.g., GB 15763.2), making it ideal for use in automotive side windows and shower rooms.

2.3 Optical and Thermal Stability

The light transmittance of both types of glass is similar (around 82%-91%). However, tempered glass may exhibit slight optical distortion due to surface waves caused by the quenching process. Moreover, tempered glass has a "spontaneous breakage" phenomenon (with a probability of about 0.3%-3%), caused by internal nickel sulfide impurities undergoing phase changes, leading to stress imbalance. This risk can be reduced through heat soak testing (HST).

3. Safety Performance Analysis

3.1 Safety Risks of Ordinary Glass

Ordinary glass used in buildings is prone to cracking under the influence of external forces such as typhoons and earthquakes, and the flying fragments may cause secondary injuries. According to the U.S. Consumer Product Safety Commission (CPSC), over 20,000 injuries occur annually due to glass breakage.

3.2 Safety Design of Tempered Glass

In addition to its breakage safety, the wind pressure resistance of tempered glass can be 1.5 to 2 times that of ordinary glass. Experimental data shows that 6mm tempered glass can withstand 5000 Pa wind pressure (equivalent to a level 12 typhoon), whereas the same thickness of ordinary glass fails at 3000 Pa. However, it is important to note that the overall strength of tempered glass will decrease drastically if the edges are damaged (such as chipping).

4. Application Scenario Guide

4.1 The situation where ordinary glass is preferred

Areas that require post-processing (e.g., artistic glass carving)

Low-cost temporary buildings (construction time < 2 years)

Applications requiring high optical precision (e.g., microscope slides)

4.2 Fields Requiring Tempered Glass

Construction safety regulations: exterior windows of buildings over 7 stories, glass curtain walls larger than 1.5 m² (according to Chinese standard GB 50449)

Areas with frequent human contact: shower partitions, mall guardrails

Transportation: Side Windows of automobiles, high-speed rail carriages (to be used in conjunction with laminated glass)

5. Special Types and Emerging Technologies

5.1 Semi-tempered Glass

Semi-tempered glass has a strength between ordinary and fully tempered glass (enhanced by 2-3 times). When it breaks, it retains some larger fragments but poses no risk of flying shards. It is suitable for places that require some degree of safety but need to avoid complete collapse (e.g., large display cabinets).

5.2 Composite Technology Development

Laminated tempered glass (PVB interlayer) combines the high strength of tempered glass with the anti-penetration property of the interlayer and has been widely used in high-end scenarios such as bank bulletproof glass and sky screen domes. In 2024, a domestic company developed "super-tempered glass" using nanocoating technology, which improves impact resistance by an additional 40%.

6. Purchasing and Maintenance Tips

6.1 Quality Identification Methods

Polarized Light Observation: Tempered glass shows colorful stress lines.

3C Certification Mark: A genuine product has a permanent marking on their edges.

Fracture Test: The number of fragments within a 50×50 mm range should be ≥40 pieces.