Heat Strengthened Glass

Heat Strengthened Glass Product

Annealed float glass can be cut to a desired finished size and Heat Strengthened to provide a glass product with greater resistance to thermal, mechanical or impact loads. Heat Strengthened glass is not a safety glazing product and must not be used in areas where safety glazing products are required by law or by building code, or where human impact is a concern. Heat strengthened glass is commonly used:

- when thermal stresses will exceed the strength of regular annealed glass (i.e. Spandrel glass)

- when larger particles in the event of breakage are desired

- to minimize risk of “spontaneous” breakage in fully tempered glass.

Heat Strengthened glass is available in 1/8”, 3/16”, and 1/4” thickness, subject to a minimum size of 4”x10” and a maximum size of 84” x 144”. Clear, Tinted, Reflective, Low E, and most Rolled Pattern Glass can be heat strengthened. Glass products with extremely uneven surfaces can not be heat strengthened.

The heat strengthening process adds distortion and changes the glass surface, factors that should be considered if appearance is critical.

Heat Strengthening Process

The heat strengthening process is the same as the tempering process except that the lower air pressure is used during the quench cycle.

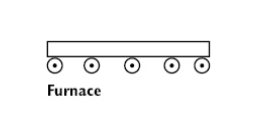

Syracuse Glass Company fabricates heat strengthened glass with a UNIGLASS state-of-theart electrically heated horizontal furnace with the latest technological innovation in heat treating – convection. The glass is conveyed into a heating chamber where it oscillates on ceramic rollers until it reaches a temperature of approximately 1200 degrees Fahrenheit.

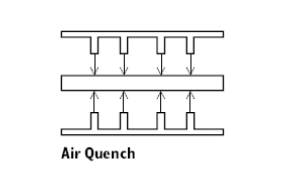

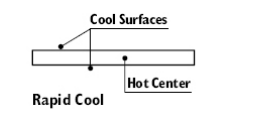

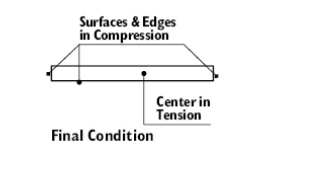

The glass exits the furnace into a quench chamber where it is rapidly cooled by air driven through a series of nozzles by two six hundred horsepower motors. The air is directed to both surfaces of the piece of glass uniformly - top and bottom. The quench process locks the top and bottom surfaces and edges in a state of high compression around a central core in compensating tension. The compression zone is about 20 percent of the glass thickness from each surface, surrounding a center core tension zone of about 60 percent of the glass thickness.

Properties

• Heat Strengthened glass has about twice the mechanical and thermal strength of annealed glass of equal thickness.

• Heat Strengthened glass is not a fire-rated glass product.

• The color, clarity, chemical composition and light transmission characteristics of glass remain unchanged after heat strengthening.

• Heat Strengthening does not reduce glass deflection under load. Glass deflection can be reduced by using glass of greater thickness.

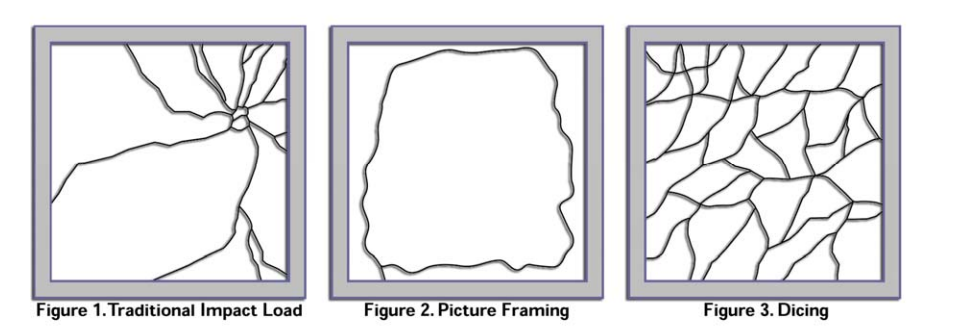

• Heat Strengthened glass tends to break into large fragments, similar to annealed glass, as illustrated in figures 1-3, depending on the intensity of the load and other factors.

• Heat Strengthened glass can not be used in hazardous locations as defined by law or building code, or where human impact is a concern.

• Heat strengthened glass can not be cut or drilled, sandblasted or etched, or edge polished or ground. Any fabrication or field alteration will weaken or break the glass.

• Tempered glass is subject to rare spontaneous breakage caused by one or a combination of these causes: surface or edge damage, deep scratches or gouges, severe weld spatter, missile or windborne debris impact, glass to metal contact, wind/thermal loading or rare inclusions or impurities in the float glass that weaken the compression layer of the glass. Breakage may occur long after the damaging event, seemingly for no apparent cause due to thermal or wind cycling. Because heat strengthened glass is produced with a lower level of compressive stress, it is even less likely to experience “spontaneous breakage”.

• When tempered glass breaks, the resulting small pieces tend to vacate the framing system under lateral load. Heat strengthened glass are less likely to leave the framing system in the case of breakage and subsequent lateral load. Laminated glass is even less likely to leave the framing system if broken. Page 3 of 3 Revised 11-05-07 Heat Strengthened Glass Product Data Sheet

• When viewing heat strengthened glass in certain conditions, a pattern of iridescent spots or darkish shadows may become visible. This is the strain pattern created by the quench process. Sharp viewing angles, polarized light, thick glass, and glass coatings increase the visibility of the strain pattern.

• The original flatness of glass is slightly modified by the heat strengthening process, causing reflected images to be more distorted than annealed glass. Warp, bow, and roller distortion are inherent characteristics of heat strengthened glass. Syracuse Glass Company produces product among the best in the industry, but distortion of reflected images can not be entirely eliminated with even the best equipment and craftsmanship.

• As a result of hot glass contact with ceramic rollers, some glass surface changes will occur. Minute glass particles (fines) from the glass cutting and edging process, and airborne dust may adhere to one or both glass surfaces. Also, the physical contact of the soft glass surface with the rollers may result in a marking of the glass surface. These surface conditions are typically not visible to the eye under normal viewing conditions. Heat Strengthened glass surfaces should not be cleaned with razor blades or metal scrapers.

• Sizes, locations, and quantities of holes and notches in heat strengthened glass must be governed by ASTM C1048 guidelines.

• Heat strengthened glass must have seamed or polished edges.

• Heat strengthened glass is supplied with a permanent mark in one corner identifying the manufacturer, Syracuse Glass Company and the words “heat strengthened” unless ordered “no logo”. Properties Cont.

Heat Strengthened Glass Product Data Sheet

Certifications:

Heat Strengthened Glass Products manufactured by Syracuse Glass Company meet the requirements of :

• ASTM C1036 Standard Specification for Flat Glass

• ASTM C1048 Standard Specification for Heat Treated Flat Glass

Thank you

Tony En

Shandong Wensheng Glass Technology Co Ltd

0086-15169185915